Bent Lamination Strength Testing

Standard test method for evaluating stress cracking of plastics by adhesives using the bent beam method.

Bent lamination strength testing. This method should be considered more severe since the angle of peel is greater. The curved line in the air forming zone shows how springback changes at different bend angles. Figure 3 coining bottom bending and air forming affect stressstrain properties differently. D7914 d7914m 14.

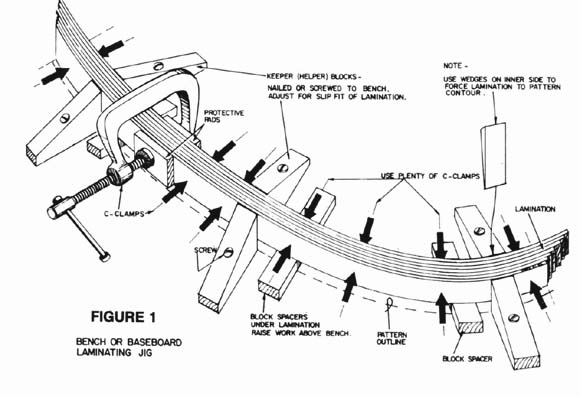

The method is of particular value for acceptance and process control testing. D5041 98 2019 standard test method for fracture strength in cleavage of adhesives in bonded joints. It has been my experience that the amount of spring back is influenced by the number of laminates thickness of the laminates species of wood cut of the grain plain sawn quarter sawn etc type of glue. The strength reduction indicated by this formula is considerably less than.

I would think that the strength of a bent laminated piece comes largely from the fact that the grain runs down the entire length plus as you bend them rotated strips are likely to break on the grain lines. Standard test method for strength of fiber reinforced polymer frp bent bars in bend locations. Astm d903 uses a 180 peel to determine the peel or stripping strength. Tests have indicated that the ratio of the strength of a curved member to that of a comparable straight member is given by the factor 1 2000 t r 2 where t is the lamination thickness and r is the radius to which the lam ination is bent.

Standard test method for bond strength of fiber reinforced polymer matrix composite bars to concrete by pullout testing. In bottoming and coining bending methods that usually produce 90 degree bend angles the line curves to the right of the vertical axis showing how the metal springs forward to conform to the die angle. I have done a great deal of bent wood laminations over the years for circular stair handrails and to my knowledge no such formula exists. D5573 99.

It may be used as an alternative to astm d1781 climbing drum test. Materials with high tensile strength and hardness such as the 400 series stainless steels tend to exhibit brittle failure whereas materials such as mild steel and the 300 series stainless steels tend to have ductile failure. I don t think that orienting alternating layers at 90 will add any strength. D7957 d7957m 17.

Physical testing of packaging products by peeling can tell us a lot about its properties and manufacturing process such as sealing consistency bonding strength adherence ability cohesive properties of the interface bond durability and other parameters. There are two primary reasons for performing a peeling test. The testing procedure used for the ewf measurement obeyed the validity criteria of the concept and we determined can be considered to be a good measure of the plane stress toughness of the composite.